Pro Top ROOFING PROJECTS

Pro Top ROOFING PROJECTS

Church Re-Roof: GAF PVC Membrane System

Commercial

This project highlights a full re-roof of a local church, a complete transformation from an aging tar-and-gravel system to a modern, high-performance roofing solution. Our team at Pro Top ROOFING was trusted to handle every stage of the process, from tear-off to final installation, ensuring long-term protection for this community landmark.

Preparation: During the removal of the existing roof, multiple wet areas were discovered within the old insulation, confirming significant water infiltration. To restore integrity and improve energy efficiency, the entire system was replaced down to the deck.

Installation: We installed 4 inches of new ISO insulation to deliver superior thermal performance, followed by a 60 MIL GAF PVC membrane. The membrane was expertly welded for a seamless, watertight finish, designed to withstand extreme weather while keeping the building dry and efficient year-round.

Scope & Delivery: This was a full tear-off and rebuild completed with precision and care. The upgraded PVC membrane roof offers not only reliable waterproofing but also long-lasting durability, helping preserve the structure beneath and providing peace of mind for years to come.

Grain Dryer Installation: Insulated Metal Panels

Agricultural / Industrial

This project involved the precise installation of supplied insulated metal panels on a new grain dryer system, a detailed and time-intensive build completed with Pro Top ROOFING’s signature attention to craftsmanship.

Installation: Each panel was carefully positioned using a vacuum lifter to ensure safe handling and perfect alignment. The installation required meticulous accuracy to maintain consistent lines and a clean finish across all elevations.

Custom Finishing: To complete the system, our team fabricated and installed custom trim work throughout the structure, providing a seamless, professional appearance. We also integrated custom drains and downspouts at the customer’s request to ensure effective water management from the top down.

Scope & Delivery: Though technically demanding, this project was completed with precision and pride. The result — a durable, weather-resistant finish that enhances both the functionality and appearance of the agricultural structure.

Roof Transformation: DuroLast Installation on Custom Home

Residential

We’re proud to highlight one of our recent residential projects just outside Ancaster, Ontario, where our team at Pro Top ROOFING was trusted to complete the flat roofing system on a beautifully designed custom home. This project showcased both form and function — pairing technical roofing expertise with a high-end aesthetic finish. Here’s how we brought it all together:

Preparation: To ensure long-term performance and effective drainage, we began with the installation of a 2% slope package. This engineered base ensures water flows away from the roof’s surface, minimizing the risk of pooling and future damage — a key component for flat roof systems.

Installation: With the slope in place, we installed the DuroLast 60 MIL membrane, a high-performance roofing material known for its strength, energy efficiency, and clean finish. The membrane was robotically welded, ensuring a seamless, watertight result that’s built to last through every season.

A unique finish: What made this project truly stand out was the homeowner’s choice of Midnight Bronze — a sleek, modern finish that adds depth and elegance to the home’s architecture. According to our supplier, this is the first known residential installation of Midnight Bronze DuroLast membrane in Ontario, making it not only a high-performing roof but also a design-first milestone.

Scope & Delivery: Our task focused exclusively on the flat roof portion of the home, and we completed this section with meticulous attention to detail. Every seam was clean, every transition sealed with precision. The result is a durable, low-maintenance roofing system that complements the home’s upscale design while delivering top-tier weather protection.

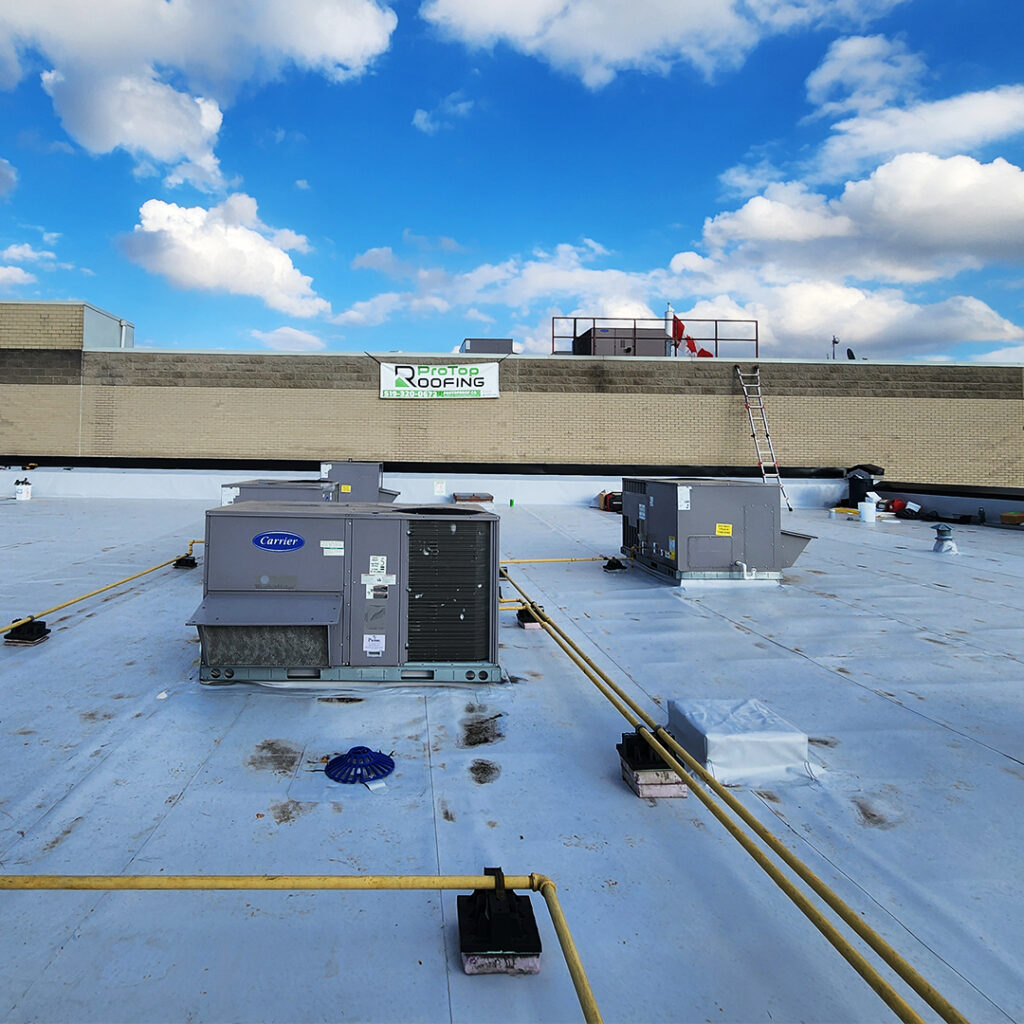

Roof Transformation: DuroLast Installation

Industrial

We’re excited to share the details of our recent reroof project at White Coad, featuring the industry’s leading DuroLast Membrane! This premium 80 MIL material ensures long-lasting durability and performance. Here’s how we accomplished this project:

Preparation: We laid a Fanfold coverboard over the existing torch-on material, creating a solid foundation.

Installation: The roof was covered with the 80 MIL DuroLast membrane, mechanically fastened and welded in place using a robotic welder for maximum precision.

Custom Solutions: All HVAC units and drains received their own custom skirts and boots, expertly crafted by DuroLast.

Logistics: Materials and tools were seamlessly lifted onto the roof by Adams Building Supply, ensuring smooth project execution.

Oversight: As this was our first DuroLast installation, the project was overseen by the DuroLast installation and sales team, ensuring quality and adherence to standards.

We’re now awaiting the final inspection by DuroLast, after which their warranty will be issued for this project. A big thanks to everyone involved for making this a success!

Restoring: Membrane Roof Repair

Industrial

In this recent repair project, we removed a large metal vent hood and a stack that were previously installed for the building’s tenant. Our team expertly insulated, covered, and sealed both areas with high-quality membrane, ensuring the roof is returned to its original state.

The client requested that the roof be restored to how it was before the space was rented, and we delivered it with precision and care. Now, the roof is ready to perform like new, seamlessly sealed and insulated for optimal protection.

Elevating Efficiency: New Insulated Panel Roof Installation

Industrial

Pro Top ROOFING is proud to announce the successful completion of a new insulated panel roof installation. In this project, we transformed an outdated roofing system by replacing old steel panels and insulation with advanced, energy-efficient materials. The project began with the careful removal of the existing steel panels and insulation. Our experienced team ensured that the old materials were removed safely and efficiently, preparing the roof for the new installation. We then proceeded to install state-of-the-art insulated panels, which offer superior thermal performance and durability. These panels are designed to provide excellent insulation, reducing energy costs and enhancing the overall comfort of the building. The new insulated panel roof not only improves energy efficiency but also significantly extends the lifespan of the roof, providing long-term value and protection. With this installation, Pro Top ROOFING has once again demonstrated our commitment to quality and innovation in roofing solutions. Stay tuned for more updates as we continue to deliver excellence in every project.

Rapid Roof Repair: Transforming a Commercial Building in Norwich

commercial

In Norwich, a commercial building faced a pressing challenge: numerous leaks plaguing its old tar and gravel roof. With the installation of a new membrane roof planned for a later date, urgent action was imperative. At Pro Top ROOFING, we swiftly sprang into action, prioritizing the immediate need for a dry roof.

Our team embarked on the task by meticulously removing the old tar and gravel roof, clearing the way for a transformative solution. With efficiency and expertise, we installed an ice and water shield, ensuring a watertight barrier that would provide the customer with a dry roof in just one day.

Despite the urgency of the situation, our commitment to quality and customer satisfaction remained unwavering. With this rapid roof repair, we not only addressed immediate concerns but also laid the groundwork for a seamless transition to the new membrane roof in the future.

Completing the Transformation: Advanced Insulation for a Commercial Building in Norwich

commercial

In the second phase of our rapid roof repair project for a commercial building in Norwich, Pro Top ROOFING took the transformation to the next level by focusing on enhanced insulation and superior roofing materials. Following the initial removal of the old tar and gravel roof and the installation of an ice and water shield, we proceeded with laying down high-quality insulation boards. This step was crucial in improving the building’s energy efficiency and providing a solid foundation for the new roofing membrane. Next, we installed a durable 60-millimeter TPO roofing membrane. Our team ensured that the membrane was mechanically fastened and expertly welded to create a seamless, watertight barrier. This advanced roofing system not only enhances the building’s structural integrity but also offers long-lasting protection against the elements. With the completion of this phase, the commercial building in Norwich now boasts a robust and energy-efficient roofing solution that will stand the test of time. Stay tuned for more updates as we continue to deliver excellence in every project.

Crafting Elegance: Custom Timber Frame Gazebo Project

Residential

At Pro Top ROOFING, we take pride in our versatility and craftsmanship. Besides our roofing projects, we have been busy creating a stunning custom gazebo for a valued customer. This isn’t just any gazebo – it’s a true timber frame structure with a beautiful tongue and groove ceiling.

Every timber was custom-cut to perfection, and meticulous was given to ensure that every detail matched the customer’s vision. This project was a labour of love, seamlessly integrated between our roofing jobs.

The result is a impressive gazebo that showcases our commitment to quality and our ability to deliver on unique, customer-specific requests. Whether it’s roofing or custom structures, Pro Top ROOFING is dedicated to excellence in every project we undertake.

Custom Home with a Premier Roof Covering – A Drone’s Eye View

Residential

Our latest project spotlights a custom home that’s currently undergoing a transformative roofing overhaul. To capture the essence of this endeavour, we enlisted the unique perspective of a drone, piloted by my nephew, offering an unparalleled view of the work in progress. These aerial shots not only provide insight into the roofing process but also highlight the meticulous craftsmanship involved. Anticipating the completion of this exquisite home, we plan to revisit the site with our drone once the landscape flourishes with greenery, ensuring a vibrant contrast that showcases the beauty and precision of our roofing expertise.

Ridge Cap Replacement and Strategic Steel Sheet Relocation

Residential

In this meticulously executed project, our team focused on enhancing the aesthetic and functional integrity of a steel building. We skillfully replaced the ridge cap, a critical component in protecting the structure from the elements, ensuring a watertight seal at the peak of the building. Additionally, with a keen eye for detail and aesthetics, we strategically relocated some steel sheets from the back to the front of the building. This thoughtful maneuver was guided by the understanding that the new sheets would blend more seamlessly at the front, thanks to the best colour match, while the less noticeable sheets were moved to the back, where shadows conceal discrepancies. This approach not only optimized the visual appeal of the building but also reinforced its overall structural resilience.

Roof Seam Inspection and Restoration

Industrial

The process begins with an inspection of the roof seam, addressing any old patches that may compromise its integrity. We precisely clean and remove debris, paving the way for installing a custom pan. This pan is not just installed; it’s coated with a protective layer, adding a second level of defence against the elements. Our scrutiny extends to the inspection of old capping, and if needed, we adeptly remove cladding, uncovering and addressing issues like mould and saturated materials. To fortify the structure, we install new plywood, creating a custom “z” bar for a specialized cant strip. This strip is then covered with TPO for durability before seamlessly reinstalling cladding and introducing new capping, leaving your roof fortified.

Discovering Mould and Saturated Material

repairing Leaking Roof Ridge

Residential

The process begins with a thorough assessment, followed by the removal of old capping and trim to make way for a comprehensive restoration. We install a double layer of foam stripping, bolstering insulation and fortifying against leaks. Taking preventative measures, we install custom flashing to repel water and wind, complemented by the addition of new ridge capping for enhanced protection. The final touch includes the use of new fasteners, securing the entire installation and guaranteeing a steadfast and resilient finish.

Concrete deck insulation

commercial

Preparing the concrete deck with a specialized primer, ensuring optimal adhesion. Next, we apply EPDM glue, creating a secure foundation for the next step. We lay down a resilient EPDM 60-millimetre membrane on the concrete deck, covering all seams of the poured concrete.

Renovation Roof Protrusions

Industrial

We framed out existing structures where outdated air conditioners or vent pipes once stood. Next installation Poly Iso board, surpassing the insulation value of the existing roof. We taped seams and framed boxes for the seamless integration of plywood. The installation process continued with applying a robust 60-mil TPO, securing it with mechanical fasteners and welded seams. This comprehensive approach extended across over 30 protrusions on the entire roof, ensuring a unified and insulated commercial space.

and Welded Seams